FIRM"VICTOR-NORTH" LTD

Summary: Production, sale, and engineering services for column extractor that efficiently dissolves dry ores.

Examples:

The advantage of a column extractor compared with vertical and horizontal mixers is that one can achieve a high (97%) degree of saturation of solution at 96% of extraction of final product from raw material.( To achieve this goal, other methods use a cascade of mixers.)

In the column extractor there are no mixing devices or

partitions; this significantly reduces cost of production and

exploitation. During emergency interruptions of electrical power

or electrical or mechanical breakdown, mixers will cause the dry

material to settle at the bottom of the apparatus. Then, in order

to re-start the process, one must empty the mixer, leading to

considerable loss of raw material and solutions. In the column

extractor, however, the settled material can be easily dissolved

and unloaded without loss of the solution.

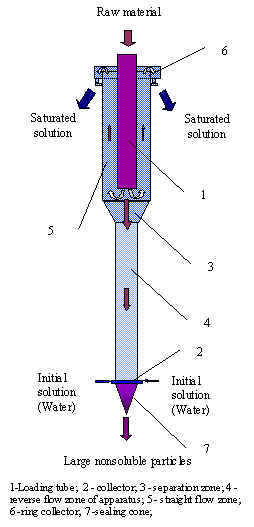

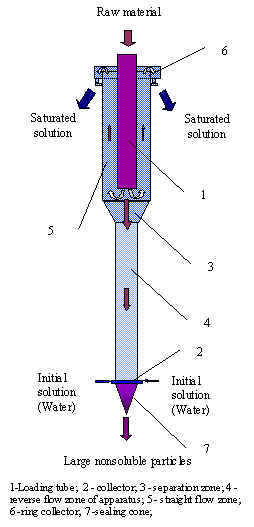

The column extractor dissolves dry raw material as follows (see diagram).Raw material comes from the loading tube (1). Initial solution (water) comes to the collector (2) in the lower part of the apparatus. At the exit point of the loading pipe is the separation zone (3) in which particles of raw material meet the upward flow of the solution. The particles become divided into large and small particles. Large particles dissolve in low reverse flow zone of apparatus (4). Small particles are carried away by the flow of the solution upward and dissolve in straight flow zone (5). Saturated solution with insoluble small particles leaves the apparatus through the ring collector (6). Large insoluble particles settle in sealing cone (7) and leave the apparatus through special bottom valve.

The heights of the upper and lower zones are calculated such that 95% is extracted soluble component from raw material at 97% saturation the solution.

The column extractor is a tested technology for obtaining chloride potassium from sylvinite ore. The output of the apparatus is 100 metric tons per hour with respect to sylvinite.

On the basis of given parameters we can design and produce a column extractor with productivity up to 500 metric tons per hour; design scheme includes ore preparation, purification of solution, and utilization of waste. Our engineering services include control of mounting and assembly, start-up, and tuning to design parameters.